It’s a pain to move or store the whole smoker only to get to the firebox, so I made it removable by welding a plate to the smoker’s base and then bolting on the firebox to that plate. The box’s latch was fabricated from a piece of scrap metal welded to the box’s side, a bar bolted to the door, and some washers and the handle from a chipping hammer. The handle for the firebox door is made from a chipping hammer, which is simple, inexpensive, and functional. The vent control is little more than some sheet metal. On the side you can bore holes for air intake and welded on a bolt so a vent control could be installed. You can kept things basic by building a square box and welded on some solid hinges for the door. The hearth is crafted from 14 “using plate steel, which is hefty but can uniformly distribute heat and maintain a constant temperature, I fabricated a simple square box and welded on some strong hinges for the door. Since a smoker doesn’t become extremely hot, you can use some pure cotton as a gasket, but you can also use felt or silicone in its place. The door to the cooking chamber was welded onto hinges, and the chamber itself was bolted together. The door was made by chopping a hole in the tank and reusing the metal that was removed. For mobility, I bolted wheels onto the frame I made out of legs. You can get as creative as you like all you really need is a flat surface for the meat to sit on while it smokes. Steps for making reverse flow smoker Step 1Īssemble all the parts Step 2: Body of Cooking Chamber. Metal Expanded for Fire Basket and Cooking Grate.

#Reverse flow smoker how to

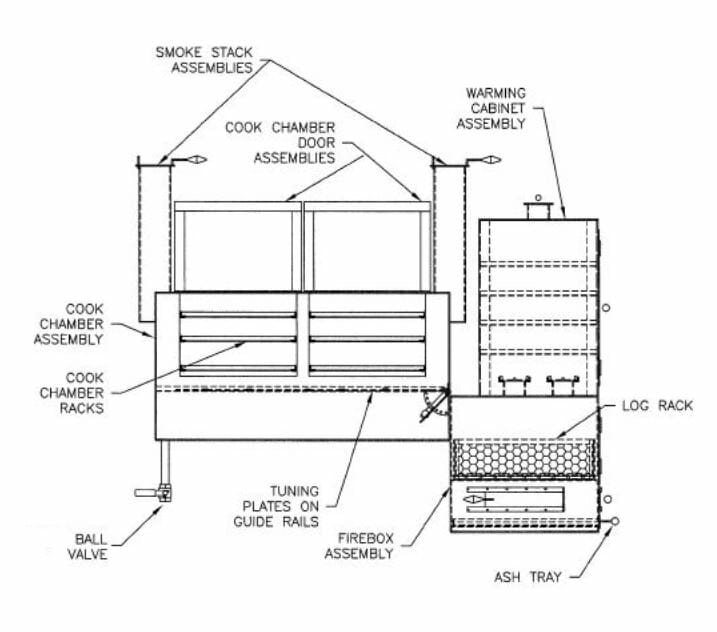

How to make a reverse flow smoker The Parts Required: DIY Reverse Flow Smoker Plans, Designs & Ideas 1. Using thick steel means less fluctuation in temperature and less work for you to maintain. The heavy steel required to construct the firebox will be the primary source of cost. This structure features both repurposed and brand-new metal components. This lets the meat soak up the smoke without being scorched by the grill. If you’re unfamiliar with a Reverse Flow Offset Smoker, it’s one in which the firebox is offset to one side of the cooking chamber and a steel baffle plate is used to divert the heat away from the meat. In this article, I will demonstrate the fundamental stages for building a reverse flow smoker. The ribs turned out absolutely delicious! The smoke from the smoker gave them a wonderfully smoky flavor that was unlike anything I had ever tasted before. Now it was time to cook some food! We decided to make some smoked ribs. The smoker smelled amazing! We let it burn for a few hours until the chips were completely charred. We filled the barrel with applewood chips and lit them on fire.

We just had to drill a few holes in the barrel and attach the pipes and fittings. It was actually very easy to put together, thanks to the clear instructions that came with the parts. A post shared by SmokerBuilder next step was to assemble the smoker.

0 kommentar(er)

0 kommentar(er)